IADC Classification System

Unlocking the Insights of the IADC Classification System for Efficient Drilling Operations

IADC classification standards, developed by the International Association of Drilling Contractors, have been the cornerstone of global drilling practices since 1940. This robust system facilitates seamless information exchange and standardized dull grading methodologies for both PDC drill bits and tricones, revolutionizing drilling endeavors worldwide. While predominantly applied to tricones, understanding the IADC classification system for PDC drill bits helps optimize drilling performance.

IADC Classification System for PDC Drill Bits

PDC drill bits nomenclature comprises a single letter and three numbers, each bearing critical significance. The letter designates the body type: M for matrix, S for steel, and D for diamond. Subsequent numbers delineate:

- Geological Formation Type To Be Drilled

- Cutting Structure

- Bit Profile

For example: M241

M=Matrix

2=Geological formation type this bit will drill

4=Cutting structure

1=Bit profile

(1) or (2) Soft and soft sticky – Highly drillable formations such as clay, marl, gumbo, and unconsolidated sands.

(3) Soft-medium – Low compressive strength sands, shales, and anhydrite with hard layers intermixed.

(4) Medium – Moderate compressive strength sand, chalk, anhydrite and shale.

(6) Medium hard – Higher compressive strength with non or semi-sharp sand, shale, lime, and anhydrite.

(7) Hard – High compressive strength with sharp layers of sand or siltstone.

(8) Extremely hard – Dense and sharp formations such as quartzite and volcanic rock.

PDC cutting structure refers to both cutter size in millimeters as well as cutter type – natural diamond, TSP, combination, and impregnated diamond.

Very soft (1) to medium (4) formation type pdc bits have one dominant size of PDC cutter. PDC cutting structure is denoted in the following way:

1 – natural diamond in any size

2 – this bit has mostly 19mm TSP cutters

3 – this bit has mostly 13 mm combination cutters

4 – this bit has mostly 8 mm impregnated diamond cutters

For example: M431

M=Matrix

4=This bit will perform well in medium formations

3=Cutting Structure consists of primarily 13 mm pdc cutters

1=Bit Profile

Harder, more difficult drilling requires types 6, 7 and 8 with their cutting structures denoted as follows:

1 – Natural Diamond

2 – TSP (Thermally Stable Polycrystalline)

3 – Combination

4 – Impregnated Diamond

Bit Profile

1 – Short Fishtail

2 – Short Profile

3 – Medium Profile

4 – Long Profile

For example: M612

M=Matrix

4=This bit will perform well in medium hard formations,

1=Cutting Structure consists of natural diamond

2=Short Profile

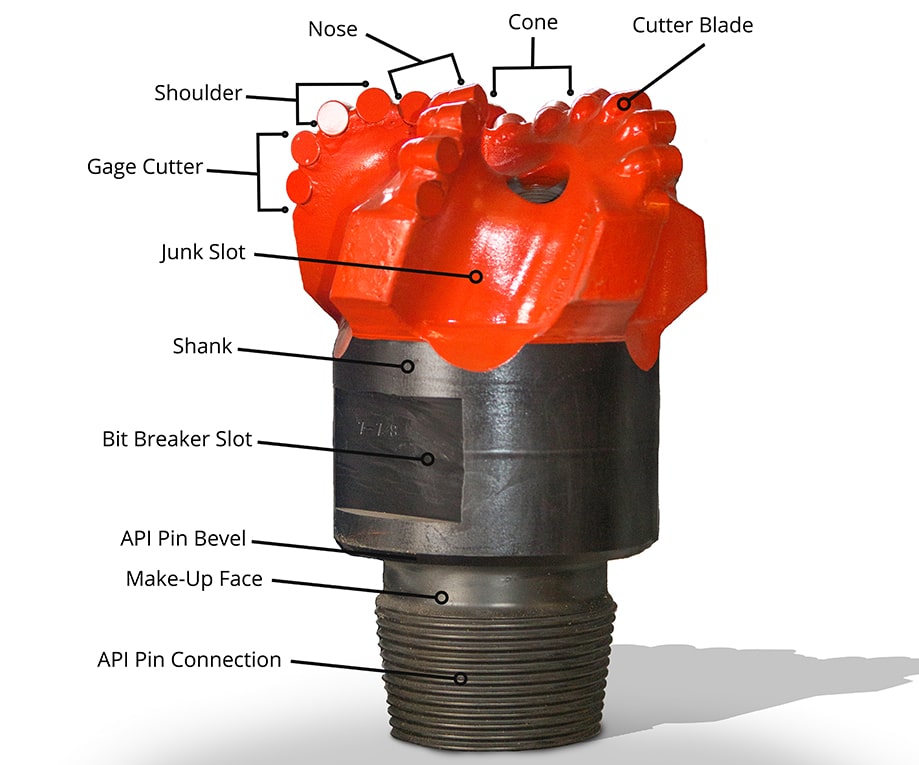

IADC Classification System For Tooth and Button Bits

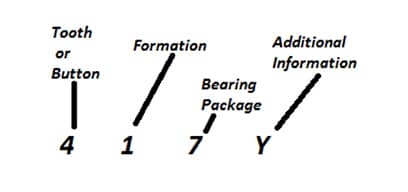

The IADC classification system for roller cone identification, established in 1987 and expanded in 1992, offers comprehensive insights into bit performance and capabilities. The first digit delineates tooth or button bits and the formation hardness they can drill, while the subsequent digits unveil bearing types and specific bit characteristics, ranging from air application to enhanced cutting structures.

The first digit denotes two things: whether the bit is a tooth or a button bit and the hardness of the geological formation it can drill.

- The numbers 1, 2, and 3 indicate a tooth bit, with 1 being used for soft formations, 2 for medium, and 3 for hard.

- The numbers 4, 5, 6, 7, and 8 denote tungsten carbide inserts designed for different formation hardnesses, with 4 being the softest and 8 being the hardest.

The second digit indicates the hardness of the formation the bit can drill. The number 1 indicates the softest formation, and 4 indicates the hardest.

The third digit indicates the bearing type. Click here for a more in-depth discussion of bearing types. The numbers 1, 2, and 3 indicate a roller bearing, 4 and 5 a sealed roller bearing, and 6 and 7 indicate a sealed journal bearing.

The fourth digit is a letter code indicating specific characteristics:

A – Air Application

B – Special Bearing

C – Center Jetted

D – Deviation Control

E – Extended Jets

G – Extra Gauge/Body Protection

H – Horizontal/Steering Application

J – Jet Deflection

L – Lug Pads

M – Motor Application

S – Standard Steel Tooth

T – Two Cone

W – Enhanced Cutting Structure

X – Chisel Inserts

Y – Conical Inserts

Z – Other Inserts

Engineering Classification for Rock Hardness

Understanding the engineering classification for rock hardness is pivotal for selecting the right drill bit tailored to the geological formation’s compressive strength. This classification categorizes rock hardness based on compressive strength, spanning from very low to very high strength formations, enabling drillers to align their tools with the specific demands of the drilling environment.

(1) or (2) Soft and soft sticky – Highly drillable formations such as clay, marl, gumbo, and unconsolidated sands.

(3) Soft-medium – Low compressive strength sands, shales, and anhydrite with hard layers intermixed.

(4) Medium – Moderate compressive strength sand, chalk, anhydrite and shale.

(6) Medium hard – Higher compressive strength with non or semi-sharp sand, shale, lime, and anhydrite.

(7) Hard – High compressive strength with sharp layers of sand or siltstone.

(8) Extremely hard – Dense and sharp formations such as quartzite and volcanic rock.

Classification Compressive Strength

Very Low Strength <4000

Low Strength 4,000-8,000

Medium Strength 8,000-16,000

High Strength 16,000-32,000

Very High Strength >32,000