In addition to the IADC Classification system, the IADC (International Association of Drilling Contractors) developed an eight-point dull grading system to enable drillers and bit manufacturers to evaluate a drill bit’s performance. This eight-point system is described below and is used to assess bit damage on both tricones and fixed cutter bits. It does not apply to drag bits.

Mastering the art of dull grading according to IADC standards is crucial. It allows engineers and sales personnel to communicate effectively and determine whether a drill bit suits the intended application or if an alternative is necessary.

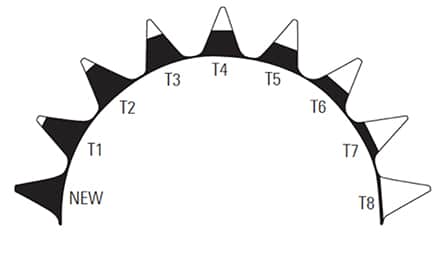

1. Inner Cutting Structure – Inner cutting structure wear is also noted by a number ranging from 0 to 8, with 0 being no wear and 8 being total wear.

2. Outer Cutting Structure—Wear in the outer cutting structure is also denoted by a number ranging from 0 to 8, with 0 being no wear and 8 being total wear.

Steel Tooth Bits

A measure of lost tooth height due to abrasion and/or damage.

0 – No loss of tooth height

8 – Total loss of tooth height

Button Bits

A measure of total cutting structure reduction due to lost, worn, and/or broken inserts. This includes button bits with either conical or chisel inserts.

0 – No lost, worn, and/or broken inserts

8 – All inserts lost, worn, and/or broken

Cutting Structure Wear

3. IADC Dull Grading Characteristics – Dull characteristics enables the bit salesperson or driller to determine the overall, distinctive aspect of the dulled drill bit according to IADC standards as follows:

BT – Broken Teeth

BU – Balled Up

CC – Cracked Cone

CD – Cone Drag

CI – Cone Interference

CR – Cored

CT – Chipped Teeth

ER – Erosion

FC – Flat Crested Wear

HC – Heat Checking

JD – Junk Damage

LC – Lost Cone

LN – Lost Nozzle

LT – Lost Teeth

NO – No Dull Characteristics

NR – Not Rerunnable

OC – Off Center Wear

PB – Pinched Bit

PN – Plugged Nozzle/Flow Passage

RG – Rounded Gauge

RR – Rerunnable

SD – Shirttail Damage

SS – Self-Sharpening Wear

TR – Tracking

WO – Wash Out

WT – Worn Teeth

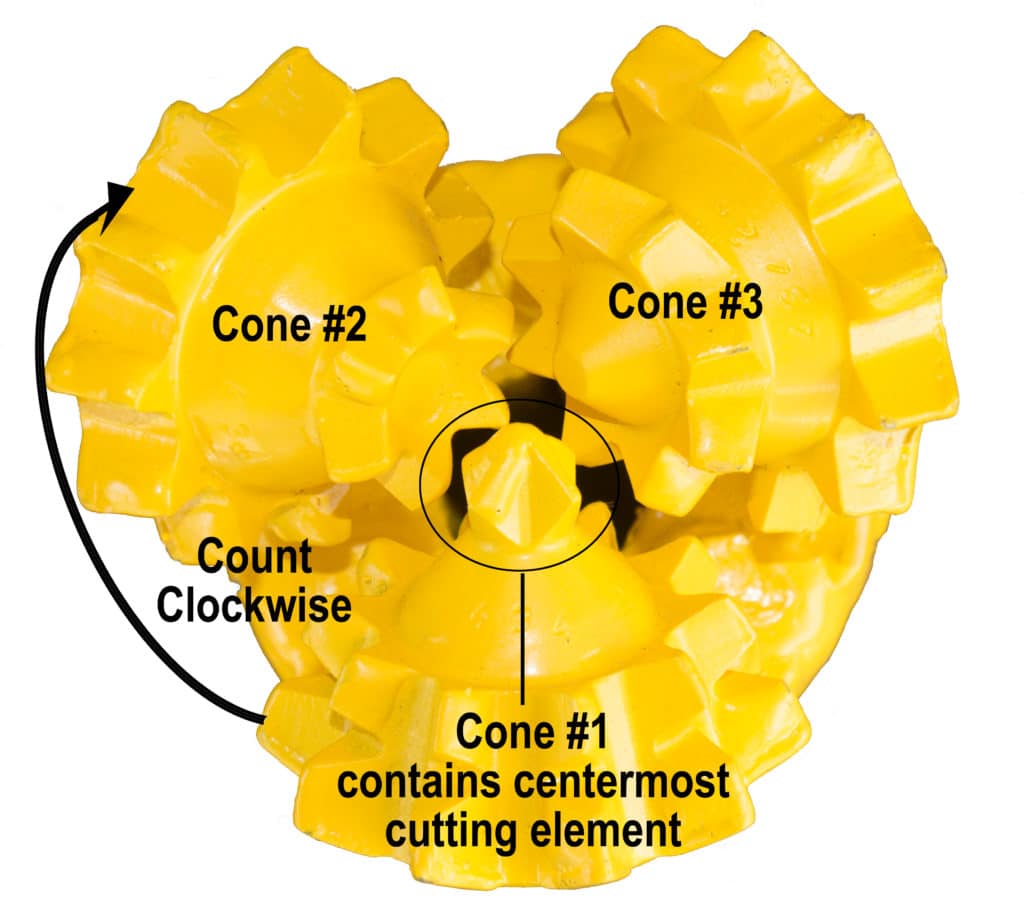

4. Location – Location describes where the damage is on the cone.

N – Nose Row

M – Middle Row

G – Gauge Row

A – All Rows

Cone Number One contains the centermost cutting component. Cones two and three follow in a clockwise manner.

- The nose row is the centermost cutting structure.

- The gauge row is the outermost cutting structure.

5. Bearings/Seals – For tricone drill bits designed as either open or roller bearing bits, bearing life is estimated on a scale of 0 to 8.

Non-Sealed Bearings

0 – No life used

8 – All life used,

i.e., no bearing life remaining

Sealed bearings

E – Seals effective

F – Seals failed

N – Not able to grade

“X” indicates fixed cutter.

6. Gauge – Gauge measures the amount of gauge wear a drill bit has suffered.

I- In Gauge

1 – 1/16” out of gauge

2 – 1/8” out of gauge

4 – 1/4” out of gauge

7. Other Dull Characteristics – Any other dull grading characteristics should be noted here using the codes from #3.

8. Reason Pulled – The following codes are used to indicate the reason a bit was pulled from the hole:

CM – Condition Mud

CP – Core Point

DMF – Downhole Motor Failure

DP – Drill Plug

DSF – Drill String Failure

DST – Drill Stem Test

DTF – Downhole Tool Failure

FM – Formation Change

HP – Hole Problems

HR – Hours on Bit

LIH – Left In Hole

LOG – Run Logs

PP – Pump Pressure

PR – Penetration Rate

RIG – Rig Repair

TD – Total Depth/Casing Depth

TQ – Torque

TW – Twist Off

WC – Weather Conditions

WO – Washout – Drill String